Energy Management

Neo’s Energy Consumption

Energy Management

At Neo, we recognize energy management as an essential aspect of sustainable operations, and this understanding extends to both our products and our global facilities. Our advanced materials enable our customers to develop highly energyefficient solutions that contribute to the broader sustainability goals. Across our operations in North America, Europe, and Asia, we are consistently striving to reduce energy usage and increase the adoption of clean and renewable energy sources. By incorporating energy management into every aspect of our business, we demonstrate our commitment to responsible corporate stewardship and contribute to global efforts against climate change. In doing so, we solidify our position as a leader in sustainability, driving positive change for both our company and the planet.

Data Collection Methodology

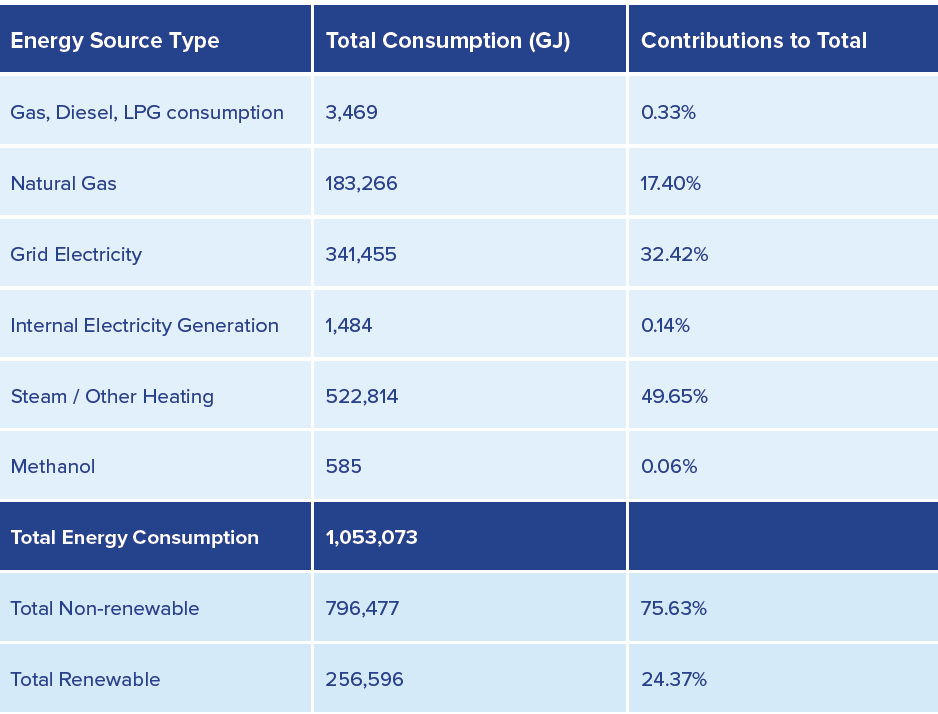

Neo’s total energy consumed in 2022 is estimated at 1.05 million gigajoules.

Neo’s energy consumption in 2022, segmented by source type:

Several of our facilities have been developing custom Energy Conservation Systems.

Zibo received ISO-50001 energy management certification in 2022.

Korat received ISO-50001 energy management certification in 2022.

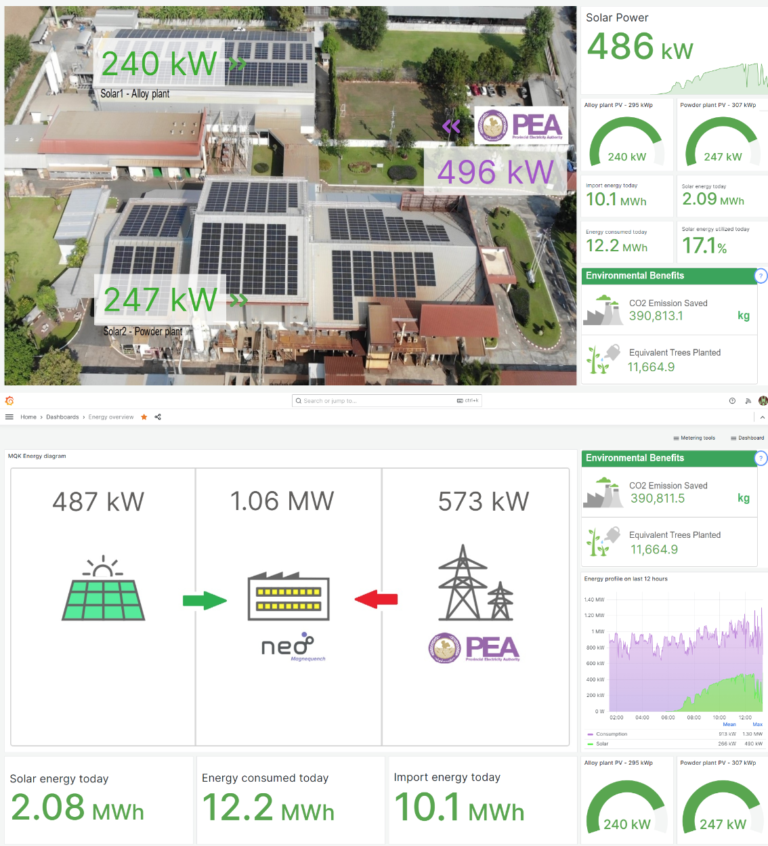

Korat, Thailand Solar Energy Project

In 2021, our Korat, Thailand facility completed a solar energy project, installing solar panels on the roof of a production building with a generation capacity of 295 kW. In 2022, Korat completed the installation of a second rooftop solar energy project, with a generation capacity of 300 kW, doubling the total solar energy capability. The combination of the two solar energy projects can generate 40% of Korat’s peak time electricity usage. This reduces the facility’s carbon footprint and alleviates pressure on the local power grid. Furthermore, to further optimize the facility’s power usage, an energy management algorithm was introduced in 2022. The algorithm works by decreasing power draw during peak times and increasing power draw during off-peak hours.

Energy Projects

In 2022, Neo’s facilities across the globe completed numerous projects aimed at reducing our energy consumption and converting to renewable and carbonneutral energy sources. The projects include:

1. Our Tianjin, China facility completed the replacement of 57 road lamps within the facility to solar powered road lamps. This project achieves energy reduction of 23,000 kWh per year.

2. Our Korat facility completed a new workshop, designed to use natural lighting throughout most of the day to reduce energy usage.

3. Our Zibo, China facility implemented a process to use remaining heat from boilers for steam production. 4,684 metric tonnes of steam were produced in the new process.

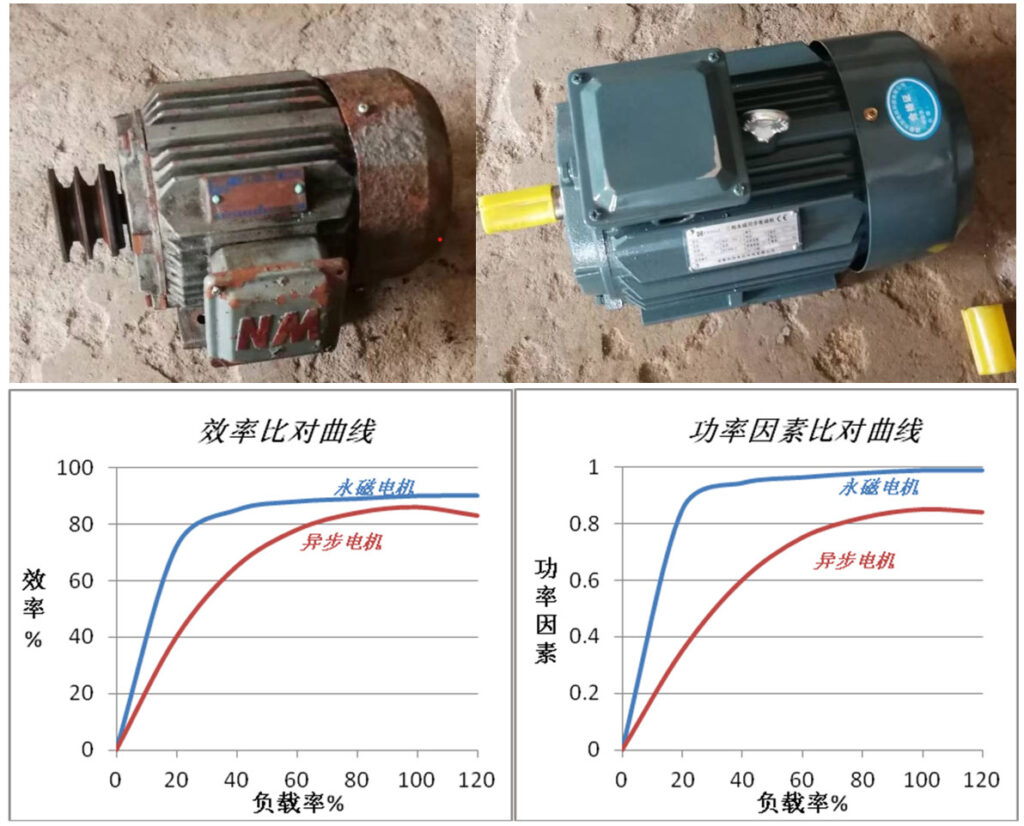

4. Our Jiangyin, China facility replaced old induction transmission motors with new, efficient permanent magnet motors to reduce energy usage, noise pollution, and CO2 emission. Efficiency is improved by a minimum of 5% and up to 30% in favorable conditions. 5. Our Sillamäe, Estonia facility completed a second heat recovery system to recover thermal energy from compressors and utilizes it as an energy input for other processes.